Stainless steel, as a low carbon steel, has been widely used in production and life. It is wear-resistant, heat-resistant, easy to clean, aesthetically pleasing, corrosion-resistant, highly ductile and long-lasting. However, stainless steel is more challenging to machine than other metals due to its high tensile strength and apparent elasticity. If you need to spin stainless steel parts, it is important to choose an experienced metal spinning service provider. They are skilled at completing the job and ensuring that the final product meets the desired specifications.

Metal fabrication specialists are not only skilled at mastering the art of spinning stainless steel, but they can also use techniques such as heating the metal so that it can be shaped more easily, as well as electro-polishing or achieving a brushed or mirror finish. This high level of service ensures that you are able to take advantage of the superior properties of stainless steel – corrosion resistance, strength, durability, and suitability for external environments – without sacrificing the overall quality of the product.

Stainless steel spinning technology offers considerable advantages over traditional stainless steel manufacturing methods:

Our technical team can produce stainless steel, aluminium, copper, silver, carbon steel and other metal parts, the following is a case study of our spinning stainless steel parts for different industries.

Product size: Φ110*250mm

Product thickness: 3mm

Material: 316

Application: Medical

Product size: Φ190*195mm

Product thickness: 2.0mm

Material: 304

Application: Dust removal equipment

Product size: Φ330*260mm

Product thickness: 1.5mm

Material: 304

Application: Mineral equipment

Product size: Φ490*10mm

Product thickness: 1.5mm

Material : stainless steel 304

Application industry:Fire truck

Product size: Φ220*200mm

Product thickness: 1.2mm

Material : SUS304

Application:Funnel

Product size: Φ480*200mm

Product thickness: 1.5mm

Material : stainless steel 304

Application :Communication

Product size: Φ300*50mm

Product thickness: 1.0mm

Material : stainless steel 304

Application: Cookware

Product size:Φ388*112mm

Product thickness: 2.0mm

Material : SUS304

Application: Fan equipment

Product size: Φ110*220mm

Product thickness: 2.0mm

Material : SUS 409

Application:Automobile tailpipe

Product size: Φ300*56mm

Product thickness: 1.0mm

Material : SUS 304

Application :Electrical appliance fittings

Product size: Φ190*195mm

Product thickness: 2.0mm

Material : 304

Application:dust removal accessories

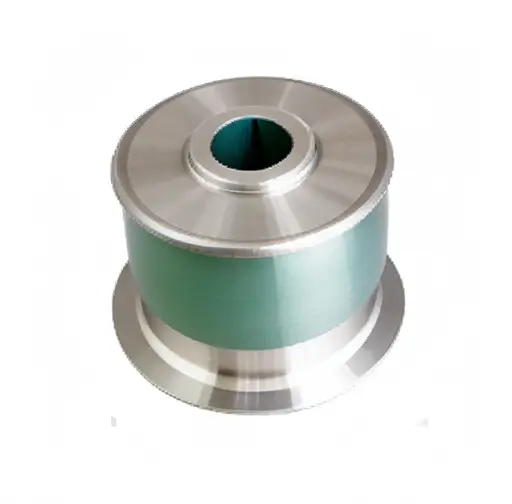

Product size: Φ180*110mm

Product thickness: 1.5mm

Material : SUS 304

Application:hardware accessories

The DY team specializes in spin forming 304 and 316 stainless steel, catering to a wide range of needs including industrial parts, cookware, aerospace components, and decorative items. We provide products with precision, durability, and aesthetic appeal, featuring seamless construction while minimizing waste.

Your industry demands excellence and efficiency, and our comprehensive spinning and stamping capabilities are designed to meet these needs. Let us assist your projects with efficient and cost-effective solutions. Contact us now to learn more or to get a quick quote based on your industry and order volume. Collaborate with us on your next project to experience a distinct quality and craftsmanship.

Leading Metal Spinning Manufacturer, We have Leifeld Spinning machines, self-developed heavy-duty spinning machines, and light-duty spinning machines for different spinning processing fields.

We will contact you within 1 hours, please pay attention to the email with the suffix “@dymetalspinning.com”.