The innovative automatic stepping trajectory programming and the infinitely variable angle tool design of the 980mm CNC spinning machine have greatly enhanced processing efficiency, overcome the limitations of traditional CNC equipment, and brought new developmental opportunities to the entire industry.

The design concept of our automatic machine is to integrate the flexibility of traditional manual spinning lathes with the precision of CNC lathes. The operation process is as natural as that of a manual spinning lathe, yet it achieves the performance standards of a CNC lathe.

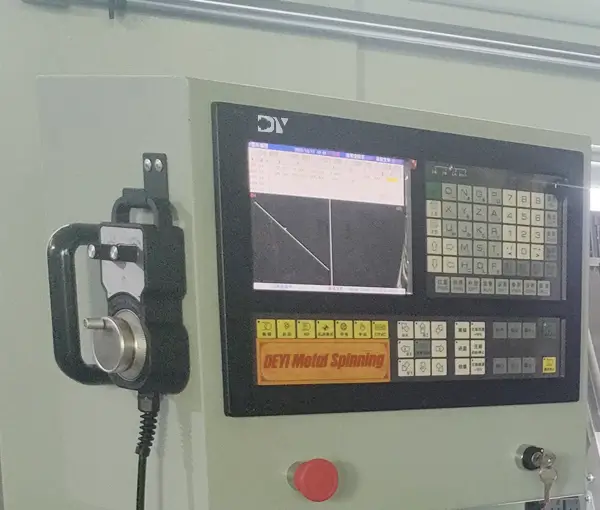

This machine avoids the cumbersome traditional programming and realizes memory functions through joystick operation, point-to-point connection, and achieves precise four-axis linkage operation.

It can easily perform forward and backward, left and right movements, accomplishing complex three-dimensional surface processing. Its mobility, flexibility, speed, diversity, and consistency enable it to precisely complete a range of craft requirements, from smooth surfaces to complex patterns such as grooves, fine lines, and decorative patterns, making it suitable for manufacturing and processing in various fields such as industrial and mining lamps, limitless lamps, reflective lamp cups, hardware accessories, kitchen utensils, chemical containers, auto parts, fan outlets, and even military and aerospace sectors.

。

Easy and efficient operation: Users can learn to operate it within just 3 to 5 days without relying on complex CAD designs.

Innovative programming: Programming is done through direct digital input, which simplifies traditional programming steps, making it suitable for beginners, and it also supports more advanced programming operations via computer software.

Highly flexible spinning paths: Four-axis linkage (X, Y, Z, A axes) achieves precise control, and with full angle conversion of the Z and A axes, the tool can rotate at any angle to meet varying processing requirements.

Energy-saving and cost-reducing: The machine’s low power consumption (4-7.5kw) significantly reduces energy use and production costs.

Quality component selection: Key parts from well-known brands are used to ensure machine stability, enhancing overall precision and tool durability.

Significant production efficiency: The introduction of one-time forming technology simplifies multi-step manual operations, significantly improving production process efficiency.

Rapid return and broad applicability: Capable of processing various metal materials such as copper, iron, aluminum, and stainless steel, suitable for the processing of various products, and available in multiple models to meet the needs of different scales of production.

AMB frequency converter starts and stops quickly, brakes smoothly, accelerates and decelerates evenly, and is highly reliable.

Screw guide rail adopts Taiwan brand to ensure precision and durability.

Infinite tool angle change

Fully automatic lubrication system is used for the lubrication of the screw guide.

Easy to learn programming

The machine is made of ductile cast iron, through normalizing and high frequency vibration to eliminate the internal stress, to ensure the overall precision of the machine tool, with excellent rigidity, excellent resistance to twisting and tilting.

| The Specification and Basic Technical Parameters Table | |||

|---|---|---|---|

| Brand: DEYI | |||

| ITEM | UNIT | Model No.980 | |

| Machining Thickness Range | Aluminum | mm | 0.38-5.0 |

| Copper | 0.38-4.0 | ||

| Iron | 0.38-2.2 | ||

| Stainless Steel | 0.30-1.8 | ||

| Maximum Machining Diameter | mm | 1000 | |

| Voltage(As Your Required) | V | 380V 50HZ 3Phase | |

| Total Number of Control Axis | Axis | 5 | |

| Accuracy for X,Y,Z,A axis | mm | 0.02 | |

| Maximum Stroke of Tailstock Tip | mm | Standard: 400 | |

| Total Electricity Consumption | kw | 13.7 | |

| Machine Overall Dimension L*W*H | mm | 3000*1900*1900 | |

| Total Machine Weight | kg | 4500 | |

| Customization: All Specification can be customized as per your required. | |||

| √ Machine Function: Curling, Flanging, Trimming, Necking, Rolling, and so on. | |

|---|---|

| √ Available For Machining Metal Material: Silver, Aluminium, Copper, Iron, Stainless Steel,and so on. | |

| Machine Features: 1.-8. | 1.High Precision; |

| 2.High Efficiency; | |

| 3.Superior Quality; | |

| 4.Superior Flexibility; | |

| 5.Machining Diversity; | |

| 6.Superior System Stability; | |

| 7.Easy Programming Operation; | |

| 8.Owned Special Programming System Based on Handworked Spinning Process Technique; | |

We do not share your personal information with third parties. By clicking the button, you consent to the processing of personal data.

Leading Metal Spinning Manufacturer, We have Leifeld Spinning machines, self-developed heavy-duty spinning machines, and light-duty spinning machines for different spinning processing fields.

We will contact you within 1 hours, please pay attention to the email with the suffix “@dymetalspinning.com”.