580mm CNC metal spinning lathe combines the intuitive operation of manual spinning lathes with the high precision of CNC lathes. The innovative automatic stepping trajectory programming and the tool’s capability for infinite angle transformation greatly enhance the processing efficiency.

Deyi automatic CNC spinning lathe combines the intuitive operation of traditional manual spinning lathes with the precision principles of CNC lathes, offering an efficient, flexible, and rapid manufacturing solution. This equipment does not require complex programming processes. Through its joystick memory function, it can memorize each point sequentially and complete four-axis dual-linkage operations by connecting points, achieving forward and backward as well as left and right reciprocating motions, and the natural forming of three-dimensional curved surfaces.

This machine is highly maneuverable, flexible, and versatile, ensuring consistency in the machining process and can accurately complete a variety of complex process requirements including smooth surfaces, knurls, grooves, gradual patterns, rosettes, grid patterns, trimming, bottom cutting, bottom turning, flanging, and curling. It is applicable to a range of manufacturing and processing industries, including industrial and mining lamps, electrodeless lamps, reflector cups, hardware lamp fittings, kitchen utensils, chemical containers, automotive parts, fan vents, and military aerospace products.

This light-duty CNC spinning machine caters to the market’s diverse demands with its high efficiency, energy-saving, ease of operation, and strong versatility. It combines automatic spinning with manual spinning lathes, without the need for complex programming. The innovative automatic stepping trajectory programming and the tool’s ability to transform at infinite angles greatly enhance machining efficiency, breaking through the limitations of traditional CNC machines. This brings new opportunities for the development of the entire industry.

AMB frequency converter starts and stops quickly, brakes smoothly, accelerates and decelerates evenly, and is highly reliable.

Screw guide rail adopts Taiwan brand to ensure precision and durability.

Infinite tool angle change

Fully automatic lubrication system is used for the lubrication of the screw guide.

Easy to learn programming

The machine is made of ductile cast iron, through normalizing and high frequency vibration to eliminate the internal stress, to ensure the overall precision of the machine tool, with excellent rigidity, excellent resistance to twisting and tilting.

| The Specification and Basic Technical Parameters Table | |||

| Brand: DEYI | |||

| ITEM | UNIT | Model No.580 | |

| Wall Thickness Range | Aluminum | mm | 0.38-4.0 |

| Silver | 0.38-2.5 | ||

| Copper | 0.38-2.5 | ||

| Iron | 0.38-2.0 | ||

| Stainless Steel | 0.30-1.8 | ||

| Maximum Sheet Diameter | mm | 580 | |

| Voltage(As Your Required) | V | 380V 50HZ 3Phase | |

| Total Number of Control Axis | Axis | 5 | |

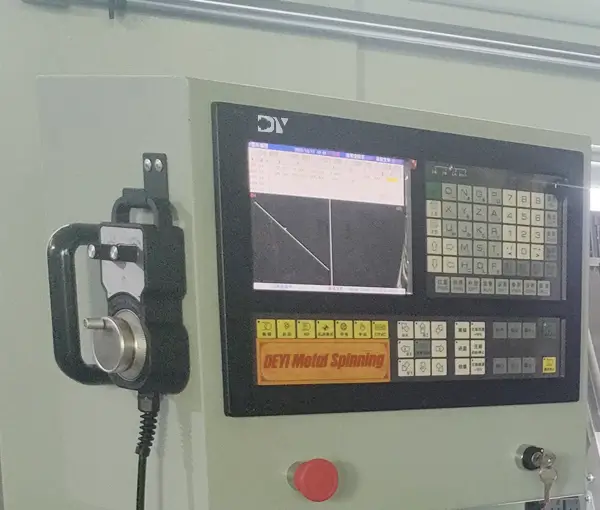

| CNC Controller Model | DEYI | Latest | |

| Accuracy for X,Y,Z,A axis | mm | 0.02 | |

| Maximum Stroke of Tailstock Tip | mm | Standard:225; Customized: Extend to 325 | |

| Maximum Pushing Force | KN | 13 | |

| Total Electricity Consumption | kw | 10.5 | |

| Machine Overall Dimension L*W*H | mm | 2600*1500*1780 | |

| Total Machine Weight | kg | 2500 | |

| Customization: All Specification can be customized as per your required. | |||

| Remark: Specification and Technical Parameters are subjected to change without notice for improvement. | |||

| √ Machine Function: Curling, Flanging, Trimming, Necking, Rolling, and so on. | |

| √ Available For Metal Material: Silver,Aluminium,Copper,Iron,Carbon Steel,Stainless Steel,and so on. | |

| Machine Features: 1.-8. | 1.High Precision; |

| 2.High Efficiency; | |

| 3.Superior Quality; | |

| 4.Superior Flexibility; | |

| 5.Machining Diversity; | |

| 6.Superior System Stability; | |

| 7.Easy Programming Operation; | |

| 8.Owned Special Programming System Based on Handworked Spinning Process Technique; | |

Our Professional Project Manager will help you step by step. Welcome to compare price and Service

We do not share your personal information with third parties. By clicking the button, you consent to the processing of personal data.

Leading Metal Spinning Manufacturer, We have Leifeld Spinning machines, self-developed heavy-duty spinning machines, and light-duty spinning machines for different spinning processing fields.

We will contact you within 1 hours, please pay attention to the email with the suffix “@dymetalspinning.com”.