Exploring new horizons of metal spinning, Deyi metal spinning develop 350 CNC spinning machine redefines the future of manufacturing with its outstanding performance, high efficiency, energy saving, and user-friendly programming.

Setting a benchmark in the spinning manufacturing of complex workpieces. Suitable for lampshades, vases, cookware, and hardware tools, it ensures precision and high efficiency in output.

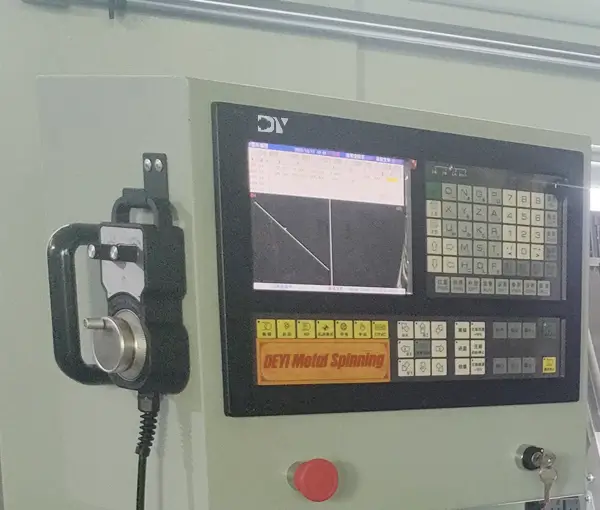

Our light duty CNC spinning machine, with its high efficiency, energy saving, easy operation, and outstanding versatility, has become the perfect response to the market’s diversified demands. Mastering the diverse metal processing market, DY-350 model spinning machine excels in processing aluminum materials with diameters up to 350mm and material thicknesses from 0.5 to 3.5mm. The equipment’s simple programming and automatic stepping technology unlock the potential of the process, enhancing simplicity of operation, and making it easy for everyone, from beginners to experts to get started. The unique energy consumption control system reduces production costs and shortens the payback period.

This machine’s revolutionary automatic pinpoint trajectory programming, combined with the infinite angle transformation ability of its tools, greatly enhances the efficiency of metal processing, while also breaking through the limitations of traditional CNC machines. As the product continues to improve and the market expands further, it is expected to gain a wider market share in the future, thereby driving progress and innovation in the entire industry

Efficiency and Ease of Collaboration: The machine’s efficiency is evidenced by operational training being completed in 3 to 5 days, without reliance on CAD drawing. Direct “foolproof” stepping programming makes digital cognition the sole requirement for programming. It also supports computer software programming and allows one person to operate multiple machines simultaneously.

Multi-Axis Precision Control: With fine motion control on the X, Y, Z, and A axes, the machine can perform precise stepping trajectory programming. The 360-degree unrestricted movement of the Z and A axes allows for infinite angle transformations with a single tool, solving the traditional multi-tool problem and greatly saving time and costs.

Low Energy Consumption Design: The machine’s energy consumption ranges between 4-7.5 kilowatts, significantly reducing electricity expenses. At the same time, it uses tiny consumable materials, reducing production cost pressures.

Material Selection and Durability: The entire machine uses high-end brand key components to ensure low failure rates and high precision, while the tools have minimal wear, providing long-term stable operation.

One-Time Forming Technology: The machine can form in one operation, even for parts that would require several steps to complete manually, now they can all be done at once by the machine.

Rapid Investment Recovery and Wide Applicability: The machine offers a quick return on investment and has a broad range of applications. It is capable of processing various materials such as copper, iron, aluminum, and stainless steel. Whether it’s smooth inner and outer lampshades, or complex crafts like deep-drawn cups and vases, they can all be easily spun into shape.

AMB frequency converter starts and stops quickly, brakes smoothly, accelerates and decelerates evenly, and is highly reliable.

Screw guide rail adopts Taiwan brand to ensure precision and durability.

Infinite tool angle change

Fully automatic lubrication system is used for the lubrication of the screw guide.

Easy to learn programming

The machine is made of ductile cast iron, through normalizing and high frequency vibration to eliminate the internal stress, to ensure the overall precision of the machine tool, with excellent rigidity, excellent resistance to twisting and tilting.

| The Specification and Basic Technical Parameters Table | |||

|---|---|---|---|

| Brand: DEYI | |||

| ITEM | UNIT | Model No. DY350 | |

| Wall Thickness Range | Aluminum | mm | 0.38-3.0 |

| Silver | 0.38-2.5 | ||

| Copper/Brass | 0.38-2.0 | ||

| Iron | 0.38-1.4 | ||

| Stainless Steel | 0.30-1.2 | ||

| Maximum Sheet Diameter | mm | 350 | |

| Voltage(As Your Required) | V | 380V 50Hz 3Phase | |

| Total Number of Control Axis | Axis | 5 | |

| Accuracy for X, Y, Z, A axis | mm | 0.02 | |

| Maximum Stroke of Tailstock Tip | mm | Standard: 175; Customized: Extend to 200 | |

| Maximum Pushing Force | KN | 4 | |

| Total Electricity Consumption | Kw | 6.7 | |

| Machine Overall Dimension L*W*H | mm | 1800*1750*1200 | |

| Total Machine Weight | Kg | 1000 | |

| Customization: All Specification can be customized as per your required. | |||

| √ Machine Function: Curling, Flanging, Trimming, Necking, Rolling, and so on. | |

|---|---|

| √ Available For Machining Metal Material: Silver, Aluminium, Copper, Iron, Stainless Steel,and so on. | |

| Machine Features: 1.-8. | 1.High Precision; |

| 2.High Efficiency; | |

| 3.Superior Quality; | |

| 4.Superior Flexibility; | |

| 5.Machining Diversity; | |

| 6.Superior System Stability; | |

| 7.Easy Programming Operation; | |

| 8.Owned Special Programming System Based on Handworked Spinning Process Technique; | |

Our Professional Project Manager will help you step by step. Welcome to compare price and Service

We do not share your personal information with third parties. By clicking the button, you consent to the processing of personal data.

Leading Metal Spinning Manufacturer, We have Leifeld Spinning machines, self-developed heavy-duty spinning machines, and light-duty spinning machines for different spinning processing fields.

We will contact you within 1 hours, please pay attention to the email with the suffix “@dymetalspinning.com”.