20 years OEM&ODM metal fabrication , mould development, metal spinning parts, metal drawing parts

+86 13016736971

MEET YOUR NEEDS

拉伸成型加工是使用模具将平板毛坯用成型模具加工词有深度,空心零件。拉伸作为主要的冲压工序之一,使用广泛。用拉伸工艺能够制成圆筒形、矩形、阶梯形、球形、锥形、抛物线形及其他不规则形状的薄壁零件,如果与其他冲压成形工艺配合,还可制作形状更为复杂的零件。

Metal spun materials commonly used in spinning include aluminum, aluminum alloys, iron, stainless steel, copper, titanium, and molybdenum. Different materials present different characteristics and application areas in the spinning process. When selecting materials, it is necessary to choose according to the specific workpiece and application areas. Below is a list of some of the more commonly used metals and common applications.

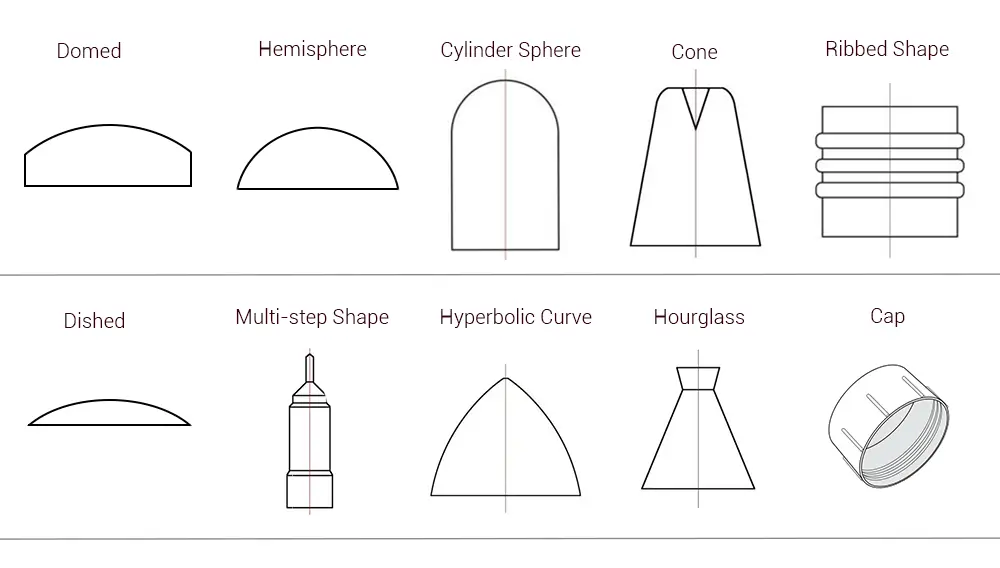

The range of metal spinning products is very wide. Depending on the capacity of the metal spinning machine, it is possible to produce large-diameter thin-walled tubes, special tubes, tubes with variable cross-section, as well as spherical, hemispherical, elliptical, curvilinear, and almost all rotating parts with stepped and varied wall thicknesses, cylinders;

| Material | Aluminum | Copper/Steel | Stainless Steel | |||

|---|---|---|---|---|---|---|

| Size | Mini. | Max. | Mini. | Max. | Mini. | Max. |

| Material Thickness | 0.3 | 15 | 0.3 | 15 | 0.5 | 15 |

| Wall Thickness | 0.2 | 5 | 0.2 | 4 | 0.35 | 2.5 |

| Diameter | 10 | 2100 | 10 | 2100 | 10 | 2100 |

| Height | 5 | 650 | 5 | 650 | 5 | 650 |

| Products | Lampshade, Auto Parts, Machinery Parts and Kitchenware, Cylinder, Tank heads and So on. |

|---|---|

| Material | 1.Aluminium: Al6061,A16063,A17075,A15052,A12017 or customize2.Stainless Steel: sus201,Sus303, SUS304, SUS316, SUS410, SUS430,SUS409L SUS441 Material 3.Brass:C36000(C26800),C37700(HPb59),C38500(HPb58),C27200(CuZn37),C28000(CuZn40) 4.white copper:C71005.lron: SPCc:DC01,DC02,DC03,DC04,DC05,DC06;SPHC:Q235,Q235B,Q345Q345B 6.Copper:T1,T2,T37.Brass Alloy:3602,2604,H59,H628.Aluminium Alloy: Al3003,AI5052,AI5083,AI6061,A160639.0ther Special Materials: gold, silver ,Carbon Steel, lron Nickel alloy orcustomize If your required material is not listed above, please contact us |

| Size | Can be customized. |

| Surface Finish | Annealing, Blacking,Natural Anodization, Heat Treatment, Mirror-polishingPowder Coating, Chrome/Zinc/Nickel Plating, Tinting, Yellow/Gold PassivationSpraying Plastics and so on. |

| Processing Method | Deep Drawing, Spinning, Bending, Stamping, CNC Machining, Tapping, Turning, Milling, Drilling, Grinding, Broaching, Welding and Assembly. |

| File format | Auto CAD, Solidworks, Pro/E, PDF, etc |

| Package | Suitable for sea and air transportation or as required |

| Certificate | ISO9001:2008, TS16949 |

| Lead Time | 10 to 20 working days according to order qty. |

Discover the difference our skilled craftsmanship can make for your projects. Fill out your contact details now and let us help bring your ideas to life. Stay ahead with our latest metal spinning innovations and services. Don’t miss out – connect with us today!”

The advantages of spinning technology are high efficiency, high precision, low cost, suitable for mass production, and widely used in various industries.

such as nose cones and housings for rockets, missiles, and satellites; penetration seals and torpedo housings for submarines; radar mirrors and searchlight housings; fairings for jet engines and parts for prime movers; and hydraulic cylinders, compressor housings and cylinders; turbine shafts, nozzles, TV cones, combustion chamber cones, and bellows; rotating drums for dryers, mixers, and scrubbers; heads, wheels and gas cylinders

Metal spinning is a machining method used to form thin-walled rotating workpieces. It is an effective method for manufacturing precision products such as hollow cones, cylindrical parts, hemispheres and thin-walled tubes. Metal spinning forming has the advantages of good surface quality, high finish, high dimensional accuracy, wide range of products and low cost.

We can produce and process cylinders and simple rotating bodies with diameters of 60-2200mm, lengths of 3000mm or less, and wall thicknesses of 0.5-40mm, as well as mass-producing thin-walled tubes of various alloys that are highly accurate and difficult to produce, and the alloys that can be spun include titanium alloys, aluminum alloys, copper alloys, and nickel-based alloys.

Metal spinning parts prices fluctuate with material, thickness, accuracy, finish, and quantity. We can process large quantities. We offer unbeatable prices that are profitable for our customers.For example, a tolerance of 0.05, diameter 50-100mm auto parts, price $0.8/pc; thickness 0.7mm aluminum lampshade, price $1.5/pc

Contact Now!

Please send your project and we have a professional engineer to cost out your project and provide a free quote.

The client selects a style, pattern, and size, or provides their design and quantity. we determine the appropriate manufacturing process and provide quotation.

For custom designs, a sample is produced within 7-12 days. Once the sample is approved by the client, the order for mass production is confirmed.

The parts are produced in accordance with the agreed-upon process and quantity. The production is transparent, and the client is kept informed of the progress on a daily basis.

Once production is complete, after quality inspection and clients conformation. the parts are carefully packaged and shipped to the client.

Purchasing directly from a metal spinning manufacturer offers significant advantages. Firstly, customers can visit the manufacturer’s production facility to observe the entire process, from material selection to spinning and final inspection. This firsthand insight ensures a comprehensive understanding of the manufacturer’s capabilities. Large-scale metal spinning manufacturers often have stringent quality standards, ensuring high-quality products. Secondly, buying from a manufacturer eliminates the additional costs associated with middlemen, leading to more economical pricing. Lastly, manufacturers often have scalable production capabilities, which can reduce the need for customers to invest in costly spinning machinery and maintenance.

Selecting a top-notch metal spinning manufacturer involves evaluating their equipment and technical staff. Advanced machinery and skilled technicians are crucial for producing high-quality components. The quality of the finished products is heavily dependent on the precision and maintenance of the equipment and the expertise of the technicians operating it.

Several factors influence the precision of metal spinning:

Spinning Equipment Performance: The accuracy of CNC spinning lathes, typically around 0.03mm, is determined by the assembly precision of the machine. High-precision equipment can produce more accurate products. However, prolonged high-load operations can wear down the machinery, affecting its rigidity and, consequently, the final product’s precision.

Metal Material Properties: The performance of the material impacts the spinning process. Different materials, like aluminum and stainless steel, have varying stress rebound characteristics, affecting the precision of the outer wall of the product. Inconsistent internal stress in the material can also cause deviations in shape, such as ovality.

Spinning Process Pathway: The choice of the spinning process pathway greatly influences the final product, especially for materials with high internal stress, like stainless steel. Adjustments in tooling and mold gap during the spinning process can significantly affect precision.

Mold Assembly Precision: The accuracy with which the spinning mold and tailstock are assembled impacts the precision of the spinning process. Lesser mold runout during spinning leads to better control over the final product’s precision.

Number of Spinning Wheels: The number of spinning wheels used can also influence precision. Generally, dual-wheel setups offer better accuracy than single-wheel configurations under the same conditions.

These factors collectively determine the quality and precision of metal spinning processes, highlighting the importance of selecting a manufacturer with the right equipment, materials, and expertise.

A wide range of metals can be used in the spinning process, including aluminum, stainless steel, copper, brass, and titanium. The choice of material depends on the desired characteristics of the final product, such as strength, weight, corrosion resistance, and aesthetic appeal. Each material has its unique properties and suitability for different applications.

Material Diameter Usage:

Processing Time:

Prototype Production Costs and Time:

Surface Treatment Costs:

Summary: Metal spinning offers reduced material usage, the potential for quicker production cycles, lower prototype costs, integrated processing, but with higher costs for surface finishing.

Contact Now!

Your own professional engineer will provide you with a free cost analysis on a one-to-one basis.

We do not share your personal information with third parties. By clicking the button, you consent to the processing of personal data.

Leading Metal Spinning Manufacturer, We have Leifeld Spinning machines, self-developed heavy-duty spinning machines, and light-duty spinning machines for different spinning processing fields.

We will contact you within 1 hours, please pay attention to the email with the suffix “@dymetalspinning.com”.